How 3D printing is innovating a tradition unlike any other

Golf is one of the oldest and best preserved sports in human history. Despite its centuries-long existence little has changed about the way the game is played. However, when victory or defeat hinges on the smallest of margins, players continually seek a competitive edge through the latest equipment innovations.

Bryson DeChambeau, the golf world's mad scientist, recently garnered attention not just for his play, but for a groundbreaking addition to his bag. During the 2024 Masters tournament DeChambeau debuted a set of 3D-printed irons, the first ever used in a professional tournament.

This marks a significant development in golf club design. To fully grasp the impact of 3D printing on golf, it is necessary to explore the physics behind a club and the manufacturing processes involved in its creation. Together, these insights reveal 3D printing is poised to revolutionize golf equipment for both professionals and amateurs alike.

Bryson’s Irons

Bryson’s irons were designed in collaboration with Avoda Golf, a partnership that began last fall. What’s unique about them compared to traditional irons is their bulge. Bulge, the horizontal curvature across the clubface, is a common feature on ‘head cover clubs’ like drivers and fairway woods. However, irons traditionally have a flat face.

Bryson suggested that adding bulge to irons improves their forgiveness, stating to the New York Post, “Most equipment is flat. These have a different curvature on the face that allows me to have my mis-hits to go a little straighter sometimes.”

To understand how a curved face can help with mis-hits, we first need to explore a concept called gear effect.

Gear Effect

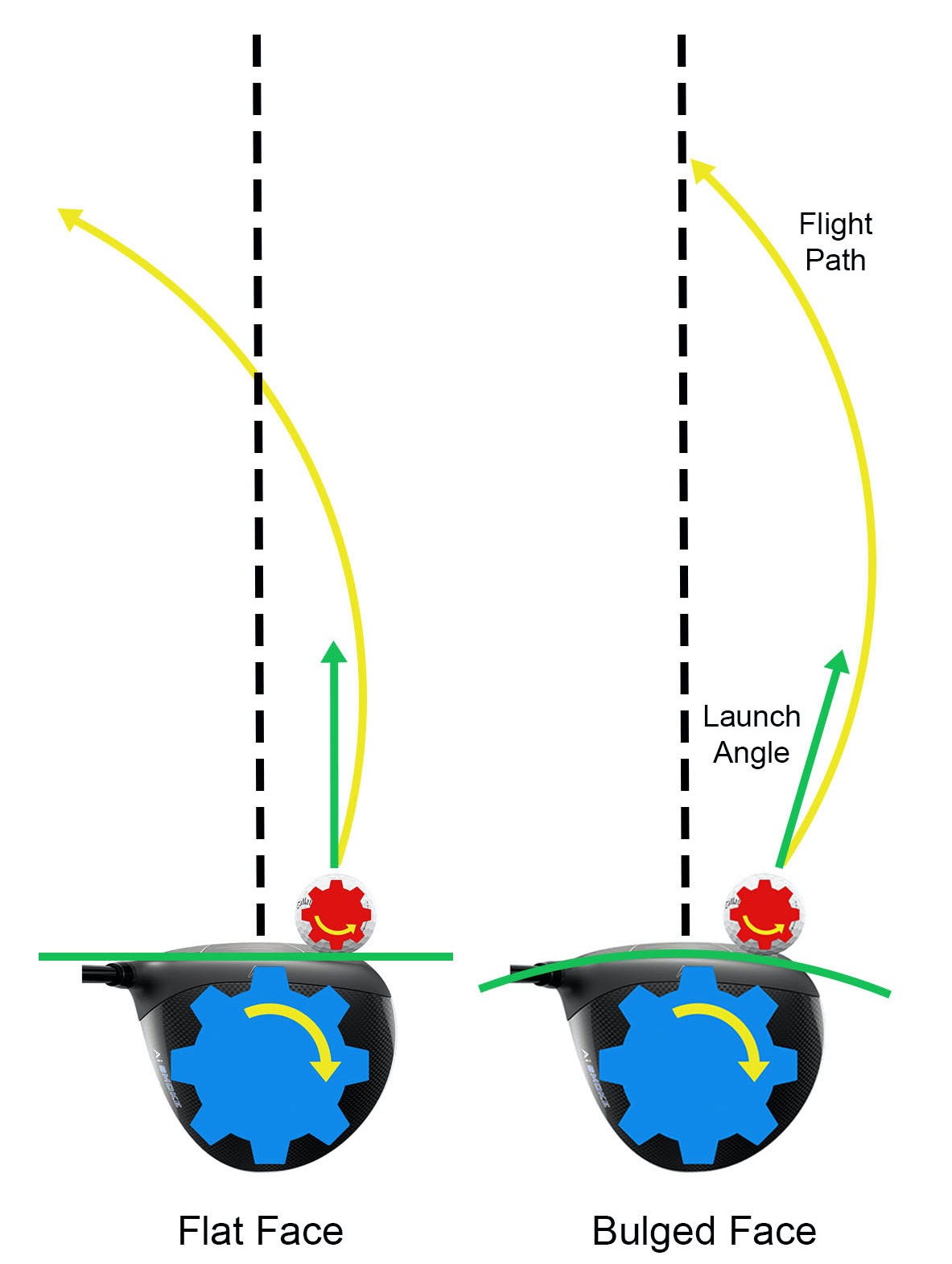

Gear effect has long been the bane of poor ball strikers. When a ball is hit off-center on the clubface, it causes the clubhead to rotate. This rotation imparts an opposite rotation onto the ball, giving it spin. Just as two gears mesh together, if the clubhead rotates clockwise, the ball will rotate counterclockwise, creating the "gear effect."

Severe cases of gear effect cause the infamous hook and slice shots, often resulting in lost balls. However, bulge helps to counteract this effect.

The farther from center a ball contacts the clubface, the greater the gear effect it experiences, imparting significant spin that causes it to curve off a straight path. Conversely, bulge sends the ball in the opposite direction of its curve. Ideally, these two forces will cancel each other out, leaving the ball in the straight center of the fairway despite its curved flight pattern.

So, will you be seeing 3D printed irons around the clubhouse?

Avoda Golf CEO Tom Bailey has said Avoda Irons have been flying off shelves since their Masters debut.

“We sold all our stock very quickly and were lucky we had more inventory on the way. Sold all that very quickly again. So right now we’re on about eight to twelve week lead time on fulfillment,” he told USA Today. He estimates he’s been assembling fifteen sets a day since the Masters.

At an average price of $1,330 a set this means Avoda has made a cool $2.4 million in gross revenue off the Masters hype. Not too bad for someone who started the company to fund his golf habit.

Avoda sells combo and same-length sets of irons. However, Bryson’s 3D printed irons with bulge are not available for sale. And there may be a good reason why.

Does a bulged iron really help?

In reality bulge does not add much forgiveness to irons due to their center of gravity. For drivers and fairway woods, the center of gravity (CG) is positioned far back from the clubface due to the large clubhead size. In contrast, irons have a much more slender design, placing their CG almost on the face of the club. This results in the CG being much closer to the ball strike point, significantly reducing gear effect.

Since the gear effect is diminished in irons, the bulge required to counteract it is incredibly subtle - so subtle that only a meticulous professional like Bryson would notice its effects. This is likely why his irons remain one-of-one for now.

While bulged irons may not be the solution your country-club friend has been seeking to improve her game, it doesn’t mean 3D printing won't be making its way into her golf bag sometime soon.

Commercial 3D printed clubs

There is an option for amateur golfers looking to access 3D printed clubs. Popular golf brand Cobra has launched the first commercially available set of 3D printed irons, named “LIMIT3D”. This move follows their introduction of 3D printed putters back in 2020.

The benefit of LIMIT3D irons is they provide the forgiveness of a concave back club, commonly used by beginners, however they have the look of a blade club that a professional would use. Ryan Roach, Director of Innovation at Cobra Golf, told Forbes, “The problem that we are solving here [with the LIMIT3D series] is that golf is a very aspirational game and people want to play something that's more like what a pro would play with, like a blade, but they need the forgiveness and features of a game improvement club. It’s really hard to marry those two together, but, with 3D printing, we feel like we have.”

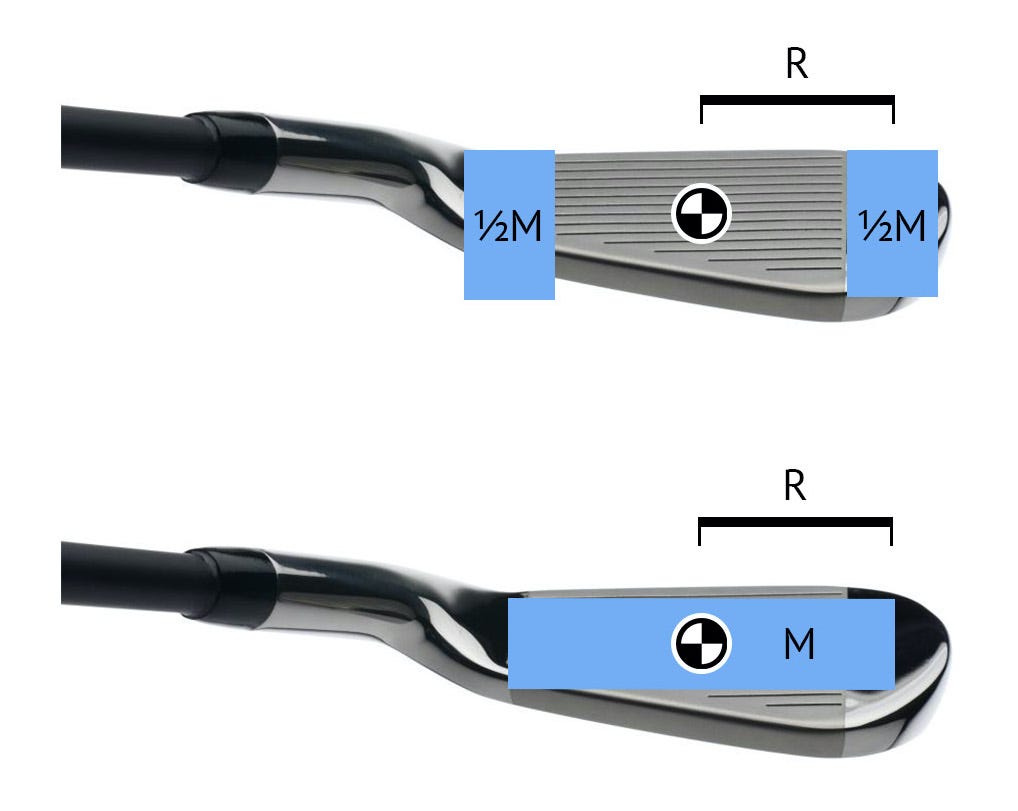

How did they accomplish this? By using 3D printing Cobra was able to create a lightweight lattice structure within the body of their club. This innovation allowed them to redistribute 33% of the clubhead weight to the heel and toe using tungsten weights. To grasp why this improves a player's game, we need to dive into a brief physics lesson on interia.

Moment of Inertia

Placing weights at the heel and toe of the clubhead increases clubhead stability when striking the ball due to moment of Inertia (MOI). MOI is an object's resistance to angular acceleration. In other words, a greater MOI means an object is more resistant to rotation. Every object has its own MOI, which depends on its axis of rotation, mass (M), and radius (R). While MOI calculations can be complex, a simple way to understand it for our purposes is that MOI increases as the distance (radius) between the axis of rotation and the mass increases.

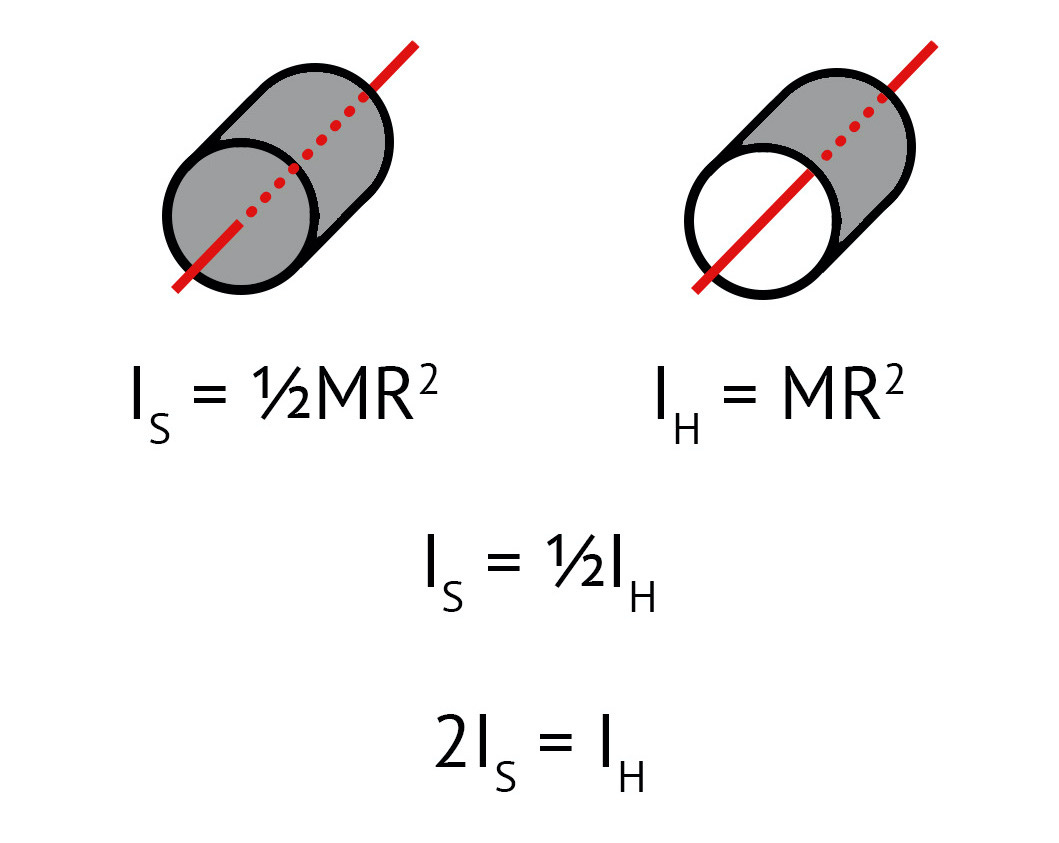

Take for example two cylinders of equal mass: one solid, and the other hollow with its mass distributed around the edges. The MOI for both the solid cylinder (IS) and hollow cylinder (IH) is shown below.

From the proof it can be seen the hollow cylinder has double the MOI of the solid cylinder, meaning it will be twice as hard to rotate. The same concept applies to golf clubs. By redistributing weight to the heel and toe of the clubhead, the head has greater resistance to rotation upon striking the ball, compared to having the weight evenly distributed throughout.

This was not the only innovation behind the LIMIT3D series, however. While Cobra’s previous 3D-printed putters were crafted using a process called binder jetting, they had to adopt a new manufacturing method for the LIMIT3D series to withstand the greater forces experienced by irons.

Powder Bed Fusion

The LIMIT3D irons were created in a process called powder bed fusion (PBF). PBF is an advanced technique in metal 3D printing that builds high-strength, intricate parts layer by layer. The process begins with a digital 3D model, which is sliced into thin layers. In the printer a fine layer of metal powder is spread across a build platform, and a high-energy laser selectively fuses the powder according to the design. This is repeated layer by layer until the part is complete, with each fused layer bonding to the one below it, ensuring a cohesive structure.

PBF can produce stronger builds than binder jetting because it fully melts the metal powder, creating dense, homogeneous parts. In contrast, binder jetting uses a binding agent to glue the powder particles together, which often requires additional sintering and can result in less dense, weaker structures. The full melting in PBF leads to superior mechanical properties and strength, making it ideal for irons.

Unfortunately, the LIMIT3D series lives up to its name, as Cobra produced only 500 sets, with a mere 300 available for sale to the public. Priced at $3,000 per set, these clubs are no small investment. Those interested in their game-improvement aspects might be better off opting for a forgiving set of cavity back irons at half the price, and using the leftover funds for a lesson… or ten.

Looking forward

The future is bright in the world of golf innovation. 3D printing has simplified the manufacturing of previously complex club designs. However, its most significant contribution might be the efficiency it brings to prototype testing. Traditionally, each prototype required a custom mold, followed by casting the clubhead with molten metal. 3D printing eliminates the need for these expensive and time-consuming molds, greatly accelerating the prototyping process. This new manufacturing method allows designers to iterate prototypes faster and more cost-effectively, fostering rapid innovation.

For golfers, this means the best is yet to come.